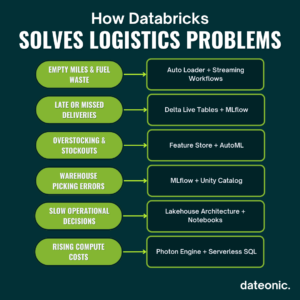

The logistics industry wastes $1.5 trillion annually on inefficiencies like empty miles, overstocking, and delayed shipments.

By combining Databricks’ lakehouse architecture with AI-powered analytics, leading companies now reduce these losses by 30%.

In this article, I reveal how Dateonic’s experts implemented:

- Real-time fleet tracking: Prevent wasted fuel and idle time

- AI demand forecasting: Cut overstocking by 35% with predictive accuracy

- Warehouse automation: Reduce picking errors by 50%

- Proven results: Case studies showing 30% cost reductions in 6 months

Databricks’ Lakehouse Architecture

The key to solving logistics waste lies in having a single source of truth for all supply chain data. Databricks’ lakehouse architecture provides exactly this foundation, combining the flexibility of data lakes with the structured query capabilities of data warehouses.

For logistics companies, this means:

- Seamless integration of structured data (order management, inventory) with unstructured data (IoT sensors, weather reports, traffic patterns)

- Real-time processing capabilities essential for fleet management

- Machine learning model deployment at scale for predictive analytics

- Cost-effective storage of massive logistics datasets

Eliminating Dead Miles and Idle Time

One of the most significant sources of waste in logistics is inefficient fleet management. According to the American Transportation Research Institute, empty miles (trucks traveling without cargo) account for approximately 20% of all miles traveled, wasting fuel, driver time, and vehicle capacity.

Databricks enables logistics companies to implement sophisticated real-time fleet tracking systems that:

- Process millions of GPS data points per second

- Integrate with traffic, weather, and road condition data

- Dynamically optimize routes based on changing conditions

- Identify opportunities for load consolidation and backhaul utilization

| Metric | Traditional Approach | AI-Optimized with Databricks |

|---|---|---|

| Empty Miles | ~20% of total fleet mileage | Reduced by up to 18% through dynamic backhaul optimization |

| Fuel Consumption | Reactive route planning, excess fuel use | Reduced by 12–20% via real-time route optimization |

| Driver Utilization | Manual scheduling, uneven workloads | Balanced workloads with predictive route & shift modeling |

| On-Time Delivery Rate | ~82% average, impacted by static scheduling | Increased to 95–98% through real-time traffic adaptation |

| Fleet Visibility | Fragmented GPS and paper-based logs | Unified, real-time tracking with millions of data points |

| Carbon Emissions | High due to inefficiencies and idle time | Reduced through load consolidation and optimal routing |

| Response to Disruptions | Delayed, manual decision-making | Instant AI-driven rerouting during delays or traffic events |

AI-Powered Demand Forecasting

Inventory management presents a perpetual dilemma for logistics providers: overstock ties up capital and warehouse space, while understocking leads to stockouts and expedited shipping costs. Traditional forecasting methods typically achieve accuracy rates of 60-70%, leaving significant room for costly errors.

By leveraging AI platforms within Databricks, leading logistics companies now achieve forecast accuracy rates exceeding 90% through:

- Pattern recognition across years of historical data

- Incorporation of external factors like economic indicators, weather patterns, and social media trends

- Anomaly detection that flags and adjusts for unusual spikes or drops in demand

- Continuous machine learning that improves with each forecasting cycle

Warehouse Automation

Modern warehouses generate enormous amounts of data through barcode scans, RFID tags, automated systems, and worker activities. Without proper data management, this information becomes siloed and underutilized.

Databricks unifies warehouse data streams to power intelligent automation:

- Computer vision systems that improve picking accuracy by 50%

- Optimized slotting that reduces travel time by 30%

- Predictive maintenance that prevents costly equipment downtime

- Labor forecasting that matches staffing to actual workload needs

One global 3PL (third-party logistics) provider implemented data-driven warehouse automation and achieved a 40% reduction in errors while processing 22% more orders with the same staff.

Data Security

Logistics data contains sensitive information about products, customers, and business operations. As companies integrate more data sources, security becomes paramount. Databricks’ Unity Catalog provides comprehensive governance for logistics data assets, ensuring:

- Fine-grained access controls across the data lifecycle

- Detailed audit logs for compliance requirements

- Encrypted data at rest and in transit

- Seamless security integration across cloud providers

This robust security framework allows logistics partners to share data confidently, creating collaborative supply chain visibility without exposing proprietary information.

Implementation Roadmap

Converting a traditional logistics operation into a data-driven powerhouse doesn’t happen overnight. Based on Dateonic’s experience with multiple logistics transformations, we recommend a phased approach:

- Assessment: Identify key waste areas and quantify their financial impact

- Data foundation: Implement a lakehouse architecture to unify siloed logistics data

- Quick wins: Deploy targeted analytics in areas with immediate ROI potential

- Scale: Expand to enterprise-wide deployment with comprehensive integration

- Innovation: Develop proprietary algorithms that create competitive advantage

Companies following this methodology typically see positive ROI within 6 months and transformative results within 18 months.

Case Study

TransGlobal, a global logistics provider, was facing rising operational costs and limited scalability with its traditional data warehouse. Partnering with Dateonic’s Databricks consultants, they migrated to a high-performance Spark environment on Databricks, achieving transformative results:

- Reduced data processing costs by 45%

- Improved route efficiency, cutting fleet fuel costs by 9.3%

- Decreased delivery estimation errors by 68%

- Enabled real-time insights with Delta Live Tables and Auto Loader

- Delivered a 280% ROI in the first year

The success hinged on a modern lakehouse architecture that unified vehicle telemetry, GPS, and weather data. Dateonic also integrated MLflow to deploy AI models for logistics optimization, empowering TransGlobal with predictive maintenance, enhanced delivery accuracy, and scalable analytics operations.

The Path Forward

According to the MIT Center for Transportation & Logistics, data-driven decision making represents the single greatest opportunity for logistics sustainability improvements. By optimizing routes, improving load factors, and reducing wasteful processes, companies simultaneously reduce costs and environmental impact.

Platforms like Databricks for enterprise data management are essential for capturing this dual benefit. Organizations that properly secure and leverage their logistics data will have a significant competitive advantage in the coming decade.

Key Takeaways

- AI and Big Data with Databricks empower companies to drastically reduce inefficiencies.

- Billions in savings and sustainability gains are achievable today with the right platform and strategy.

- Speed matters — early adopters are already capturing market advantage.

- Partnering with experts like Dateonic accelerates transformation and ensures both technical and organizational success.